Principle Green Development Safe Development

List of Responsibilities for On-site Coating Engineers

Release time:

2025-08-07

In industrial coating projects, the on-site coating engineer plays a pivotal role in ensuring coating quality. Their work spans the entire project lifecycle—from initial preparation to final acceptance—where every stage directly impacts the coating’s performance, service life, and project costs. Below are the detailed responsibilities and essential competencies of an on-site coating engineer.

Responsibilities of a Coating Engineer: Quality Control Throughout the Entire Process

In industrial coating projects, the on-site coating engineer plays a pivotal role in ensuring coating quality. Their work spans the entire project lifecycle—from initial preparation to final acceptance—every stage of which directly impacts the coating’s performance, service life, and project costs. Below are the detailed responsibilities and essential competencies required of an on-site coating engineer.

I. Core Responsibilities at Each Stage

| Stage | Responsibilities |

| Project Preliminary Stage | Read and understand the project specifications; submit a request for clarification. |

| Read and understand the product data sheets (PDS) from paint manufacturers; identify conflicts between the PDS and specifications, and seek solutions. | |

| Read the safety data sheets (SDS) for each hazardous product used in your work, and familiarize yourself with the required personal protective equipment. | |

| Attend the pre-construction meeting, obtain a copy of the pre-construction meeting minutes, and, where appropriate, document any changes or clarifications to the project specifications. | |

| Project entry safety training: Use personal protective equipment that is suitable for the conditions at the work site. | |

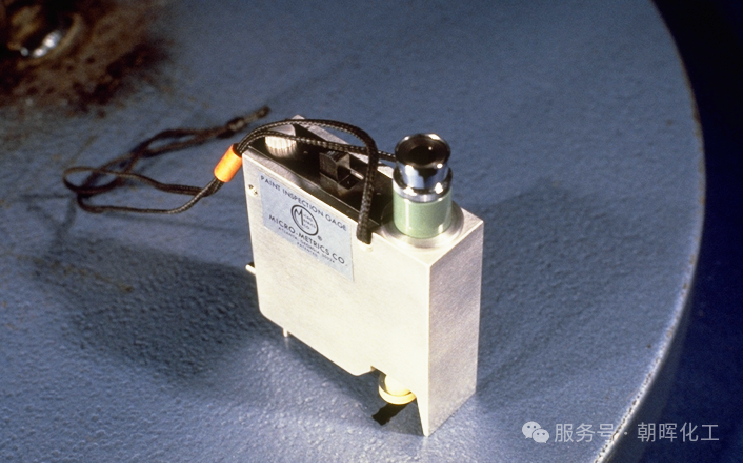

| Obtain the required inspection equipment according to the project, and verify the operation and calibration of instruments and equipment. | |

| Prepare an inspection plan | |

| Material Receiving / Storage | Check the product name, specification model, production batch number, and date of manufacture. |

| Monitor the temperature and humidity of the storage area. | |

| Record all information. | |

| Pre-surface preparation | Verify, according to SSPC-SP 1, that visible grease/oil and the like have been removed. |

| Check the coating integrity of edges, welds, and fasteners; verify the removal of spatter and overlapping layers. | |

| Inspect hard-to-reach areas within the structure and bring them to the owner’s attention for resolution (if not addressed in the specifications). | |

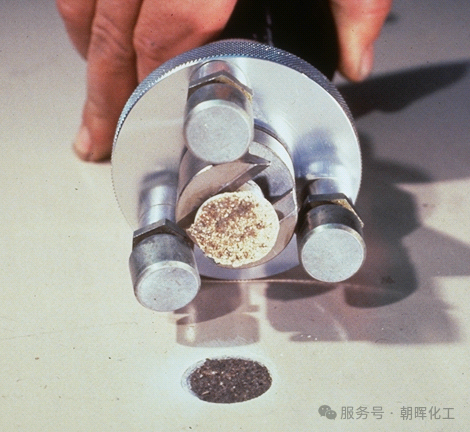

| Perform a surface-soluble salt contamination test (may also be required after preparation)* | |

| Verify that surface preparation equipment and consumables (such as abrasives) meet the specified requirements. | |

| Verify that the protective shield is in place and securely fastened, and verify that the lighting is correct. | |

| Surface preparation | Measure the ambient conditions and surface temperature before final surface preparation. |

| Indirect requirements for SSPC blast-cleaning standards: 1. Compressed air cleanliness 2. Abrasive cleanliness (water-soluble contaminants and oil) | |

| Determine the initial condition of the steel (corrosion grade). | |

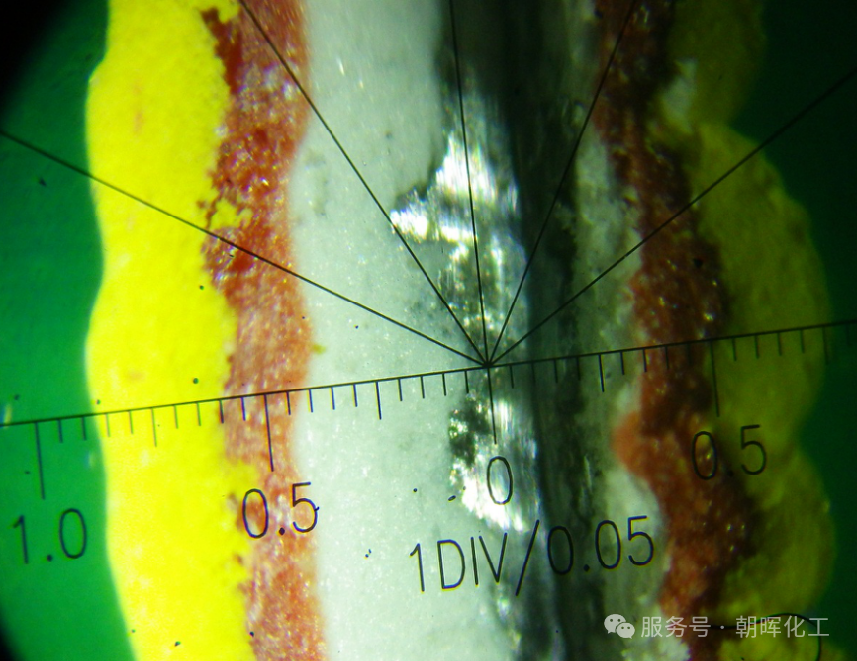

| Check surface cleanliness according to the specified standards. Verify dust removal levels using the adhesive tape replication method. | |

| When needed after preparation, check whether the soluble salts have been thoroughly removed.* | |

| Confirm that the maximum preparation time for the primer has not been exceeded. | |

| Mix / Dilute | Measure environmental conditions and surface temperature |

| Verify that the type and quantity of diluent are correct (if used). | |

| Verify the import time based on the product data sheet (PDS). | |

| Verify that the mixture is used before its expiration date. | |

| Coating Application | Throughout the entire application process, measure environmental conditions and surface temperature at the intervals specified. |

| Verification stripe coating * | |

| Measure wet film thickness | |

| Verify recoating time (minimum / maximum) | |

| Verify the cleanliness between coatings and observe the formation of amine exudates in certain types of epoxy coatings. | |

| Late stage of coating application | Measure the dry film thickness of each coating layer. |

| Perform pinhole/missing coating inspection * | |

| Perform hardness/curing tests * | |

| Perform adhesion test * |

II. The Importance of On-site Coating Engineers

The work of on-site coating engineers directly affects the smooth progress and quality assurance of the project.

Reduce rework and cost overruns. :

By rigorously controlling the quality of each stage, identifying and addressing issues in advance, we can avoid rework caused by coating defects, thereby saving time and costs.

Preventing premature failure of coatings :

Standardized inspection and operation procedures can ensure that coating performance meets specifications, extend the service life of equipment and structures, and reduce subsequent maintenance costs.

Ensure construction safety :

Safety measures and safety training based on SDS can effectively reduce safety risks during construction.

III. Essential Qualities for Outstanding On-site Coating Engineers

1. Physical fitness

Possesses the ability to climb and enter confined spaces, and can adapt to high-altitude working environments. Has excellent vision (correctable), color perception, and manual dexterity to ensure precise detection and operation. Proficiently uses personal protective equipment such as respirators and fall protection devices, enabling sustained performance even in complex environments.

2. Training and Continuing Education

Combining theory with practice: You must not only master the principles of coating application and industry standards (such as SSPC standards), but also become proficient in operating testing instruments. Continuously update your knowledge: Since coating industry standards are revised approximately every five years, it’s essential to stay current through continuing education to keep pace with new standards, emerging technologies, and safety regulations.

3. Experience

Experience and training complement each other, helping to avoid “insufficient inspections” due to lack of experience or excessive inspections that compromise construction efficiency, thus striking a balance between quality and schedule.

4. Communication skills

Communicate verbally clearly and professionally, and remain patient and calm when facing challenges. Prepare standardized written reports (such as daily inspection reports), presenting project progress with both data and narrative to provide decision-making support for owners and management.

Summary

On-site coating engineers serve as the “gatekeepers” of coating quality. Their thorough understanding of industry standards, meticulous attention to detail, and high level of integrity and professional ethics are essential to ensuring project quality. Whether it’s in the preliminary preparation stage, material acceptance, surface treatment, or coating application, rigorous execution at every step safeguards the long-term performance of the coating and ensures the smooth delivery of the project.

previous page

Latest news

ZhaoHui Chemical Suzhou Team Building Event

2025-12-09

2025-08-14