Principle Green Development Safe Development

Coating Defect Detection

Release time:

2025-08-14

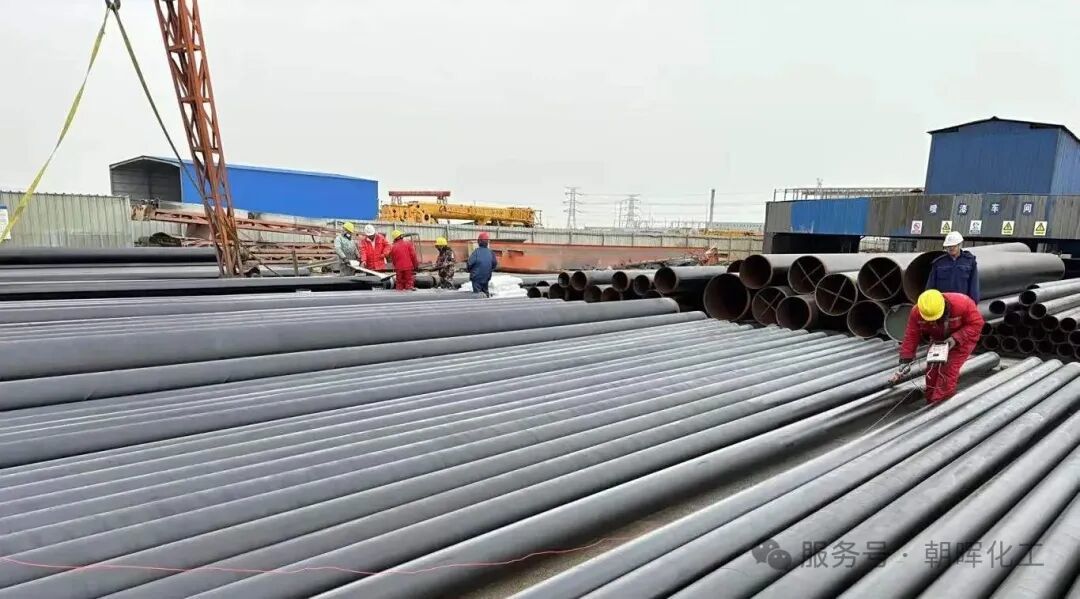

In the protection of large-scale structures such as bridges, storage tanks, and pipelines, coating systems act like a “suit of armor,” effectively shielding these structures from external corrosion and extending their service life. However, if this “armor” contains discontinuities—such as pinholes or missed coatings—it can become a hidden “entry point” for structural degradation. Oxygen and electrolytes from the outside environment can seep through these gaps into the substrate, causing corrosion of the metal base material and seriously compromising the structure’s safety and durability.

In the protection of large-scale structures such as bridges, storage tanks, and pipelines, coating systems act like a “suit of armor,” effectively shielding these structures from external corrosion and significantly extending their service life. However, if this “armor” contains discontinuities—such as pinholes or missed spots—it can become a hidden “entry point” for structural degradation. Oxygen and electrolytes from the outside environment can seep through these gaps into the substrate, causing corrosion of the metal base material and seriously compromising the structure’s safety and durability. Today, we’ll talk about how to identify these hidden coating defects through scientific testing.

What is a coating pinhole?

Coating pinholes are mainly divided into two categories:

Pinhole These are tiny gaps or needle-like pores that penetrate the coating; they may reach all the way to the substrate, or they may not fully penetrate. The primary cause is often the coating’s inability to thoroughly wet the surface—for example, when air bubbles rupture during application or when impurities remain behind.

Missing coating points Refers to areas in the coating that are not fully covered by the paint. Such issues are typically caused by improper application techniques and tend to occur more frequently in complex structures—such as hard-to-reach corners and crevices—or in concealed areas—for example, the interior of underground pipelines or the inner walls of storage tanks.

These defects may be visually difficult to detect, but once put into service, they can become a “breeding ground” for corrosion. Therefore, it is crucial to perform leak detection and repair before the coating system is put into operation.

Timing and Precautions for Testing

Leak detection isn't necessarily better the more you do—it requires seizing the right timing.

Best time: It is typically performed after the final coat of the coating system has been applied. It is not recommended to perform inspections after each coat, as surface contamination could otherwise compromise the adhesion of subsequent coats.

Scope of application: Mainly used for New Coating Applied to Metal Substrates System. For old coatings that have been exposed to immersion conditions, detection may lead to coating damage or false readings—penetration, hygroscopicity, or surface deposits on the old coating could interfere with detection results, and the sparks generated during high-pressure testing might even puncture intact coatings.

Two mainstream detection methods

Depending on the coating thickness, leak detection is mainly divided into two methods:

Wet sponge low-pressure detection

Applicable scenarios: Systems with a coating thickness of less than 500 micrometers.

Equipment composition: Metal end forceps with sponge fibers (to be thoroughly soaked in tap water), grounding wire (connected to exposed areas of the structure), and lead wire (connected to the detection device).

Working principle: When the sponge comes into contact with the coated surface, if pinholes or leakage points are present, current will flow through the gaps, forming a circuit and immediately triggering an audible alarm from the device.

Voltage setting: The voltage for the coating on steel is fixed at 67.5V, making the operation simple and easy to learn.

High-voltage spark detection

Applicable scenarios: Systems with coating thicknesses greater than 500 microns; coatings with thicknesses between 250 and 500 microns can also be used, but precise calculation and voltage adjustment are required.

Device features: It uses a metal brush, neoprene, or coil electrodes (replacing the sponge). The voltage is adjustable, and the device must be configured via calculation before use.

Working principle: The wire connects the detector and the test structure to form a loop. When a leak is detected, in addition to an audible alarm, you can also visually observe sparks, enabling more precise detection.

Summary

Both detection methods share a common premise:

The substrate must be conductive, while the coating must not be conductive. Coatings containing conductive pigments such as zinc and aluminum flakes cannot be detected using these two methods.

Coating defect detection is a critical step in safeguarding structural integrity. It enables the timely identification of hidden defects that are difficult to spot with the naked eye, thereby preventing premature failure of the substrate due to corrosion. Selecting a detection method that matches the coating thickness—whether low-voltage or high-voltage—and properly setting the relevant parameters (especially the voltage for high-voltage testing) not only ensures accurate detection results but also helps avoid damaging the coating.

previous page

Latest news

ZhaoHui Chemical Suzhou Team Building Event

2025-12-09

2025-08-14